Goodyear Welts: A Good Choice For Your Italian BeSpoke Shoes Posted on 9 Sep 11:01

The Goodyear Family's first factory was bought on the banks of the Little Cuyahoga River in East Akron, Ohio in the United States. It was an old warehouse building converted into a strawboard factory. The Goodyear family bought the building in 1898, a little while after the Goodyear welting machine was invented. No longer done by hand the Goodyear family expanded to create room for the demand they would soon find in tires and shoes.

The best bespoke shoes to this day still represent the Goodyear construction of durable materials with the ability to be as flexible as possible. The Goodyear welt named after the family is a symbol of that. While a comparison of two very similar bespoke shoes may have you stumped the difference is barely noticeable. But it can be the difference between a shoe lasting 2 years versus a Goodyear shoe lasting a lifetime.

The stitching technique allows the sole to be completely replaced when worn done, thus allowing the shoe to breathe new life until this needs to be fixed again. Thus a shoe could last as long as you, if you take care of the top half of the shoe.

The name Goodyear comes from exactly where you might expect. The same founder as Goodyear Tires. (Founder shown above).

But what came first? The tire or the Welt.

The answer is the welt of course. In 1869 by Charles Goodyear Jr., the son of Charles Goodyear, created the machinery that would eventually take over the luxury shoe market. While they did start out in bike tires and automobile tires they did transition into Goodyear Welt we use today. However using machinery is simpler it takes half the skill level to create it.

Thus the Italian artisans at Treccani Milano still use the traditional form of stitching the welt and soles together completely by hand using the expert skill passed down through many generations.

How is a welt used? Here is a step-by-step explanation of why welts are so important.

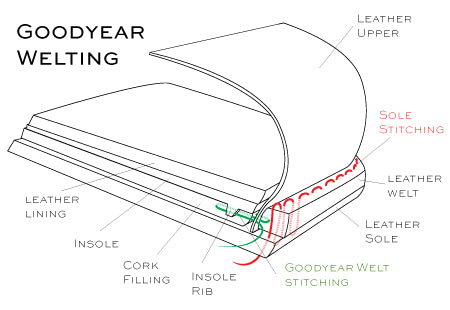

A welt typically refers to the strip of leather, rubber, or plastic that is seen along the perimeter of the outsole and then stitched to the upper and a strip of canvas. This process is known as gemming. The gemming is then cemented to the insole of a shoe, as an attach-point for the sole.

Check out this video of our artisans at work creating a shoe and stitching by hand:

Why it's important/ the best welting:

Based on the above information it is clear to see the superiority in the Goodyear welt and stitching techniques. Not only is a better quality of stitching but allows a shoe to be easily fixed and given new life. It retains the bespoke custom look while getting a small upgrade. The welt can also act as a buffer between insole and outsole, with some space created to add cork for your comfort.

You can see an example of our own stitching on the Brera Calfskin Oxford Shoes:

Sources:

http://www.stanhywet.org/history

https://en.wikipedia.org/wiki/Goodyear_welt

http://www.primermagazine.com/2014/spend/understanding-shoe-construction-goodyear-welt-blake-stich-cementing

http://www.theshoesnobblog.com/2011/07/shoes-part-1-construction.html

http://know.boga.com/blake-stitch-and-goodyear-welt-shoes/

https://corporate.goodyear.com/en-US/about/history/beginnings.html